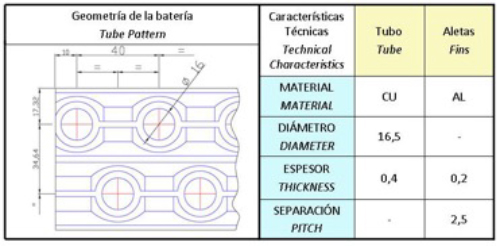

In the AVS dry cooler series the thermal exchange surface is provided by two coils mounted on V shape, built with tube and fin features according data in the technical characteristics table. The fins are of continuous sheets stamped with undulations, studied to optimize the efficiency of heat exchange, and collars maintaining the separation between them.

The tubes are mechanically expanded, ensuring effective contact with collars fins and are interconnected forming circuits designed to improve the transmission efficiency with low pressure loss.

Axial fan type formed by adjustable pitch blades anchored to a cube in injected aluminium, with high efficiency airfoil profile and moulded in polypropylene reinforced with fiberglass (PPG).

The fan cylinder and the roof of the AVA equipment are constructed in reinforced polyester, with an aerodynamic design at the outlet of the air, improving the power consumption and noise level.

The three phase electric motor, directly coupled to a axial fan, is of closed type with IP55 protection according IEC 34-5 y UNEL 05515. An hermetic connections box transferred outside of the equipment for an easy connection. Each motor / fan are equipped with a remobable fan guard made with frame and mesh in steel and hot dip galvanized after fabrication.

All components that serve as support or frame to the coil, as well as the support of the fans structure are constructed with panels or profiles of galvanized steel with thickness of 2 or 3 mm. that provides a superb consistency and firmness to the structure and bearing capacity of the machine, as well as resistance to the passage of time necessary to ensure continued service.

The legs or feet of anchor of the whole are also built with 4 mm thick galvanized sheet profiles.

All elements of the structure are subjected to a cycle of degreasing, phosphatization and applying of two-component polyurethane varnish prepared expressly for the protection of equipment exposed to air pollution.