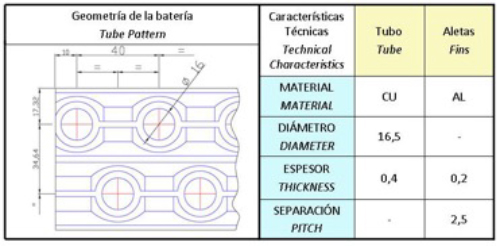

Coil built with tube and fin features according data in the technical characteristics table. The fins are of continuous sheets stamped with undulations, studied to optimize the efficiency of heat exchange, and collars maintaining the separation between them.

The tubes are mechanically expanded, ensuring effective contact with collars fins and are interconnected forming circuits designed to improve the transmission efficiency with low pressure loss.

Formed by a multi-bladed propeller made in aluminium with curved shape that offers excellent sound level, performance and adaptability to the optimal operating point.

The core of the propeller is driven by an external rotor type motor IP54 which allows different speeds depending on the type of connection.

The rotor and the impeller set, dynamically balanced at two levels according to ISO standards, is contained in a scroll stamped steel with aerodynamic profile to reduce its strength and noise level.

The protection grid anchored on the scroll, serves to support the fan motor assembly.

One of the most distinctive features of our air coolers is its robustness. Designed thinking mainly in industrial applications, they must ensure optimum performance and resistance to time running and extreme working conditions.

All components that serve as support or frame to the coil, as well as the support of the fans structure are constructed with panels or profiles of galvanized steel with thickness of 2 or 3 mm.

The legs or feet of anchor of the whole are also built with 4 mm thick galvanized sheet profiles.

All elements of the structure are subjected to a cycle of degreasing, phosphatization and applying of two-component polyurethane varnish prepared expressly for the protection of equipment exposed to air pollution.

For the protection of the coil on equipment with fans working in discharge, built with galvanized steel wire mesh, with a maximum pitch of 1 cm.